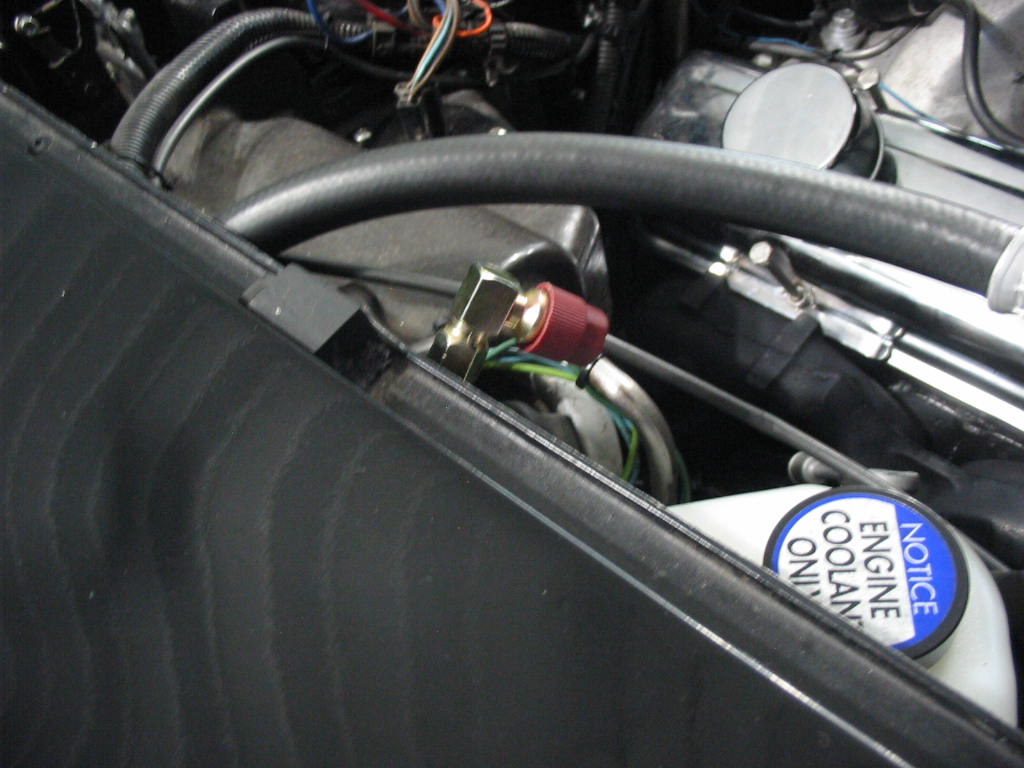

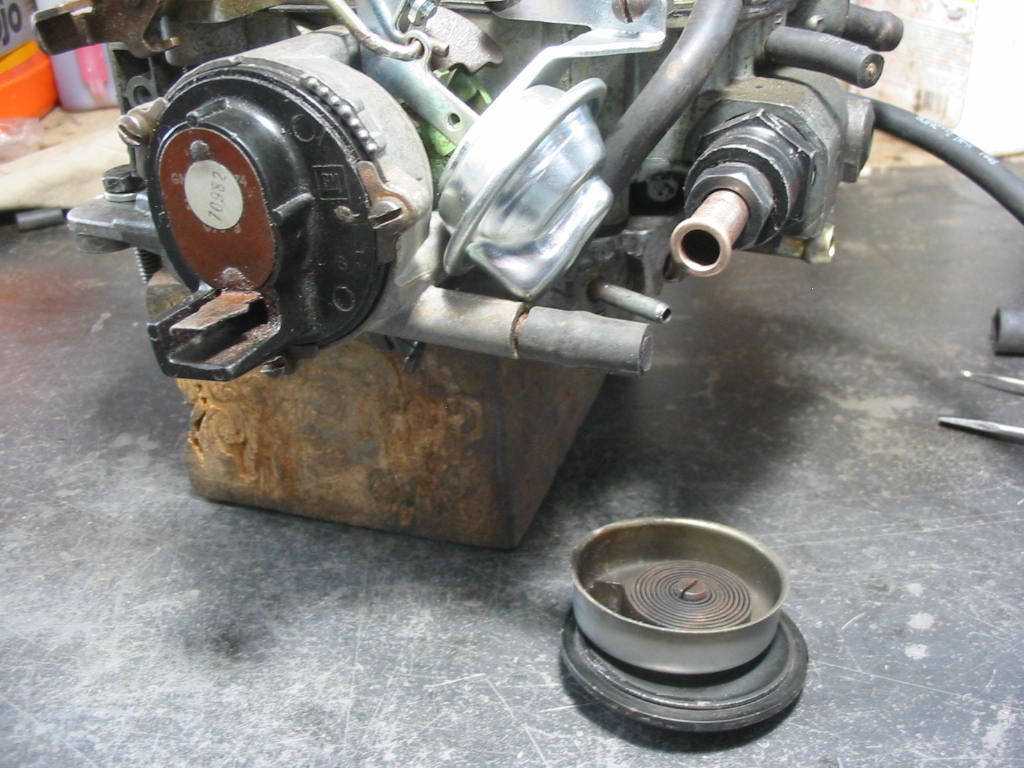

The alternator isn’t behaving itself. It shows 13+ volts when starting out, but as the engine heats up it drops the 13 and below. I have the 56 amp alternator from the ’82 Caprice. Buddy Don ran it up on his test machine and it seems to be OK and the bearings are fairly quiet. The regulator connections were a bit rusty and it’s hard to clean them in place so I opted to take the unit apart and clean up all the contacts and the corrosion on the case. The nuts and screws needed a bit of penetrating oil so they would come off easily without damaging the diode unit or regulator. I also added a tad of wheel bearing grease to the needle bearings in the back of the case.

Cleaned up the front half of the unit and then fit it back together.

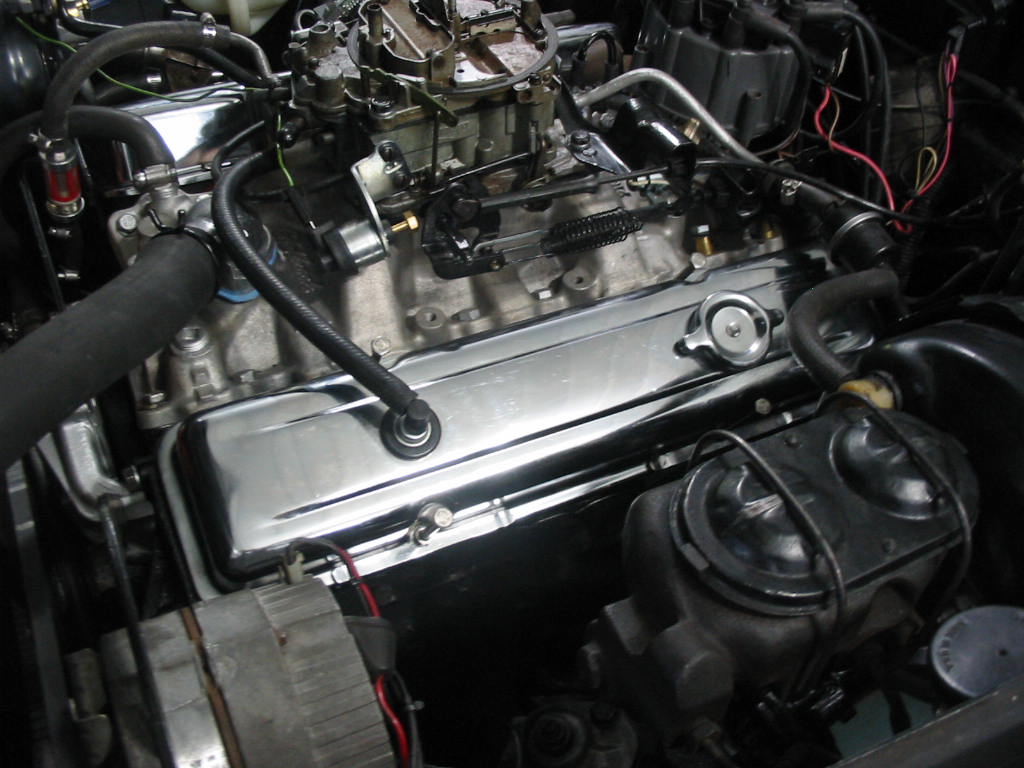

All nice and finished and ready to go. Sadly it wouldn’t generate from the get-go 🙁

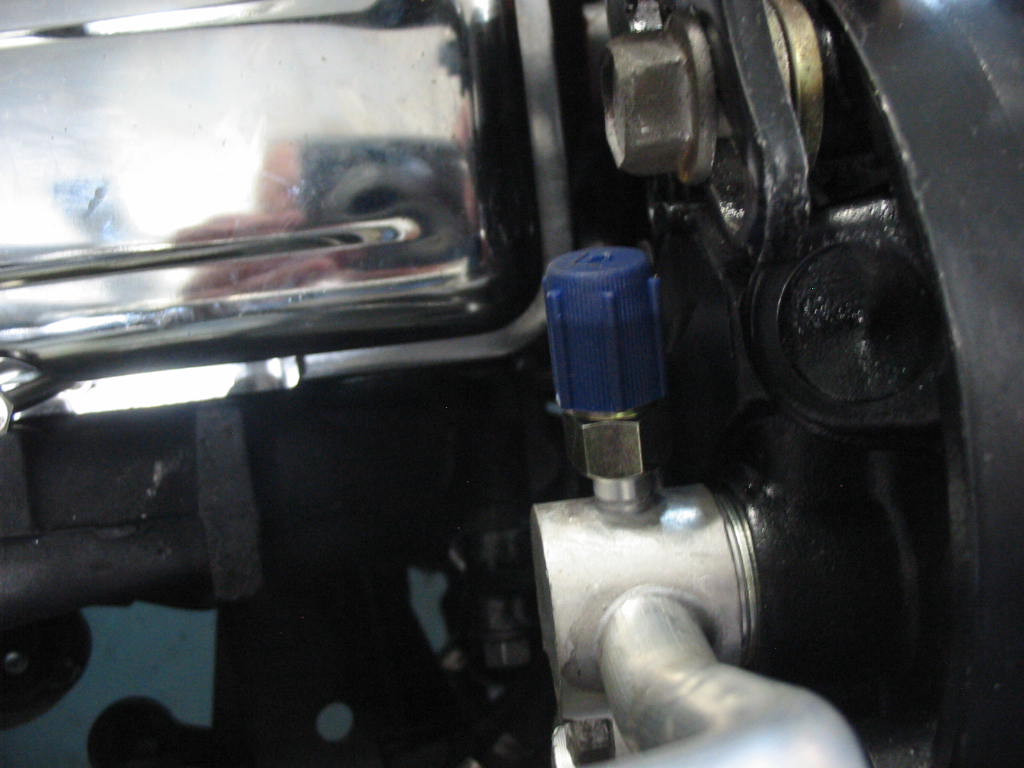

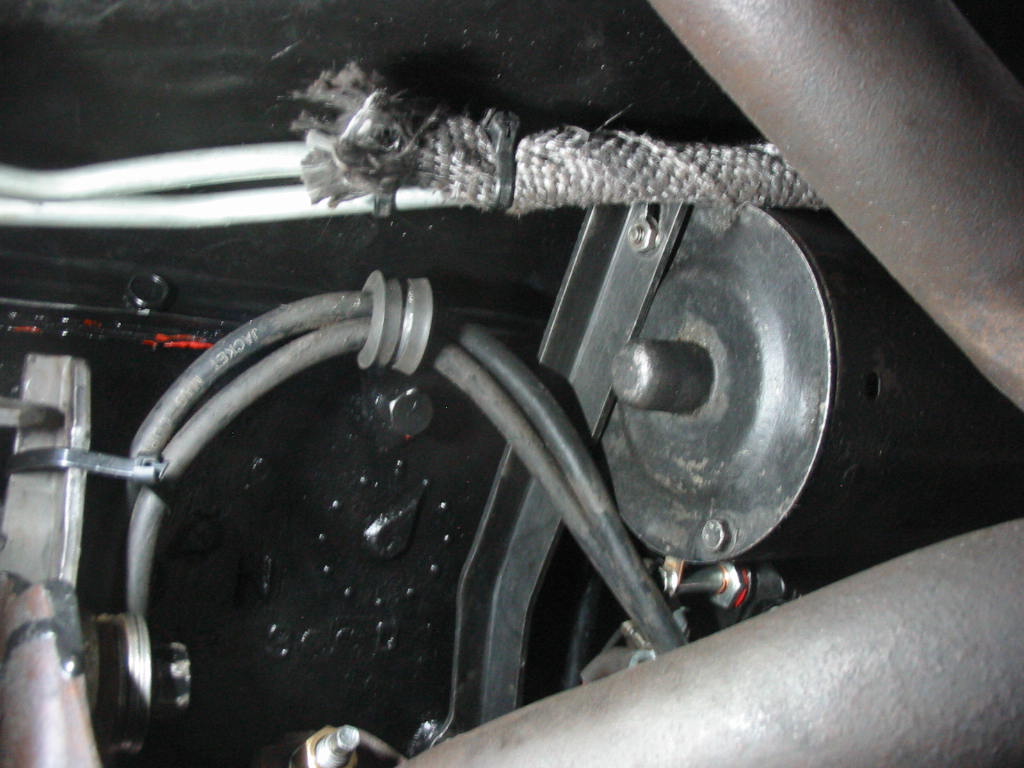

In talking to Don I remembered a side comment he made about someone changing the GEN light bulb in the dash. I then realized that I must have changed that bulb for a diode bulb when I replaced all the dash lights. The diode is on the left and the regular incandescent is on the left. With the key in the ON position I was getting a reading of about .55 volts at the R connection on the alternator (the two prong plug that goes to the alternator has a F (field) and R connectors). This is apparently not enough to trigger (excite) the alternator to start charging. After I changed the bulb I got a reading of over 2 volts and that was enough to get the alternator charging. Now there was a full 12+ volts at the R connection and the GEN light on the dash was out.

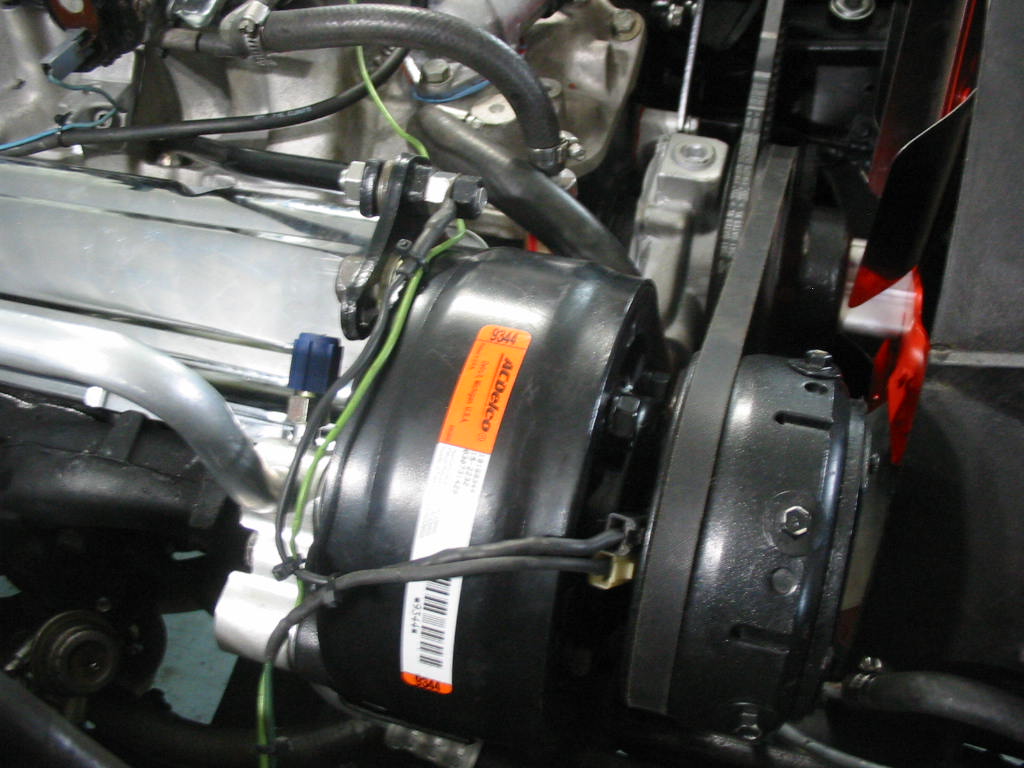

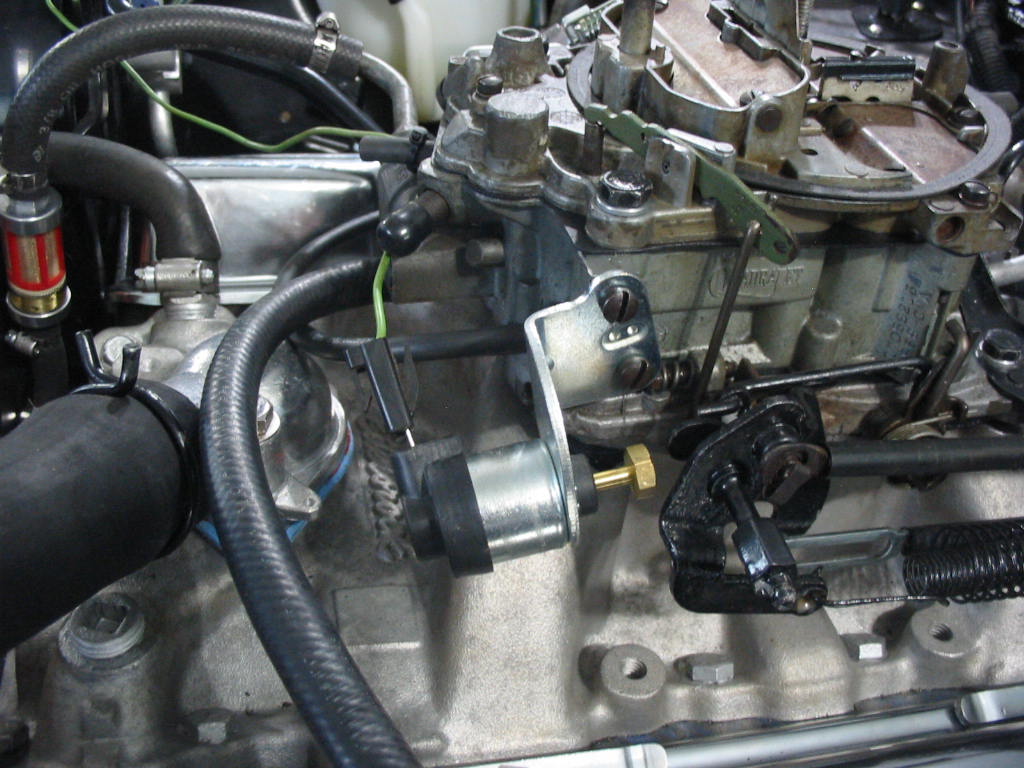

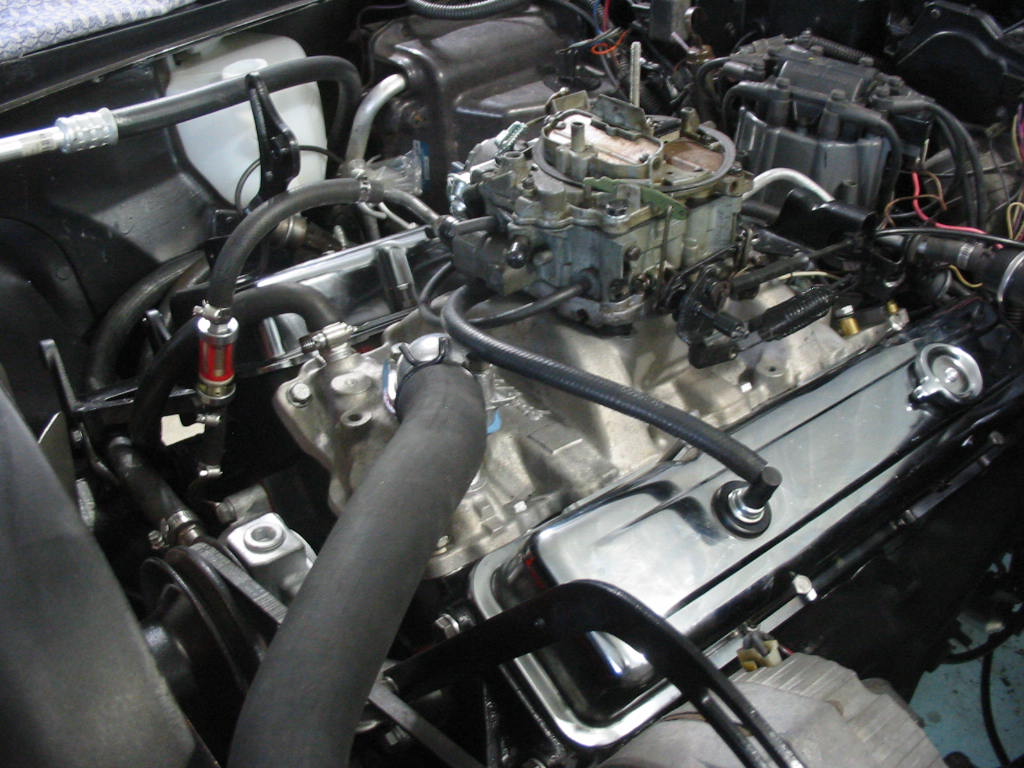

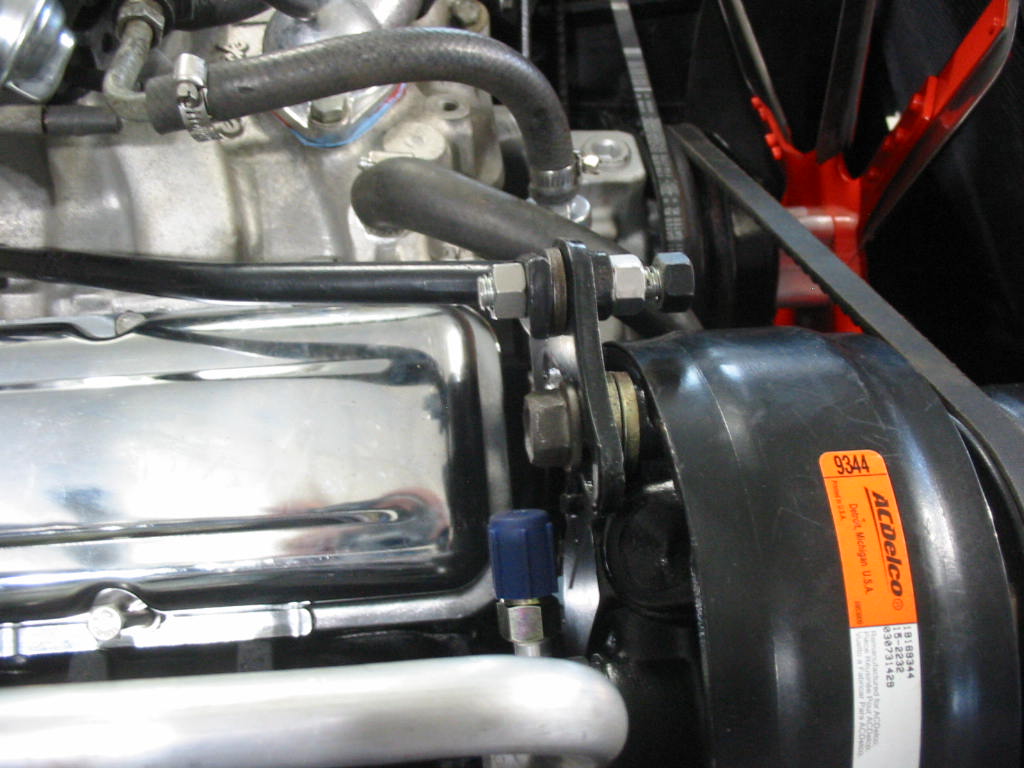

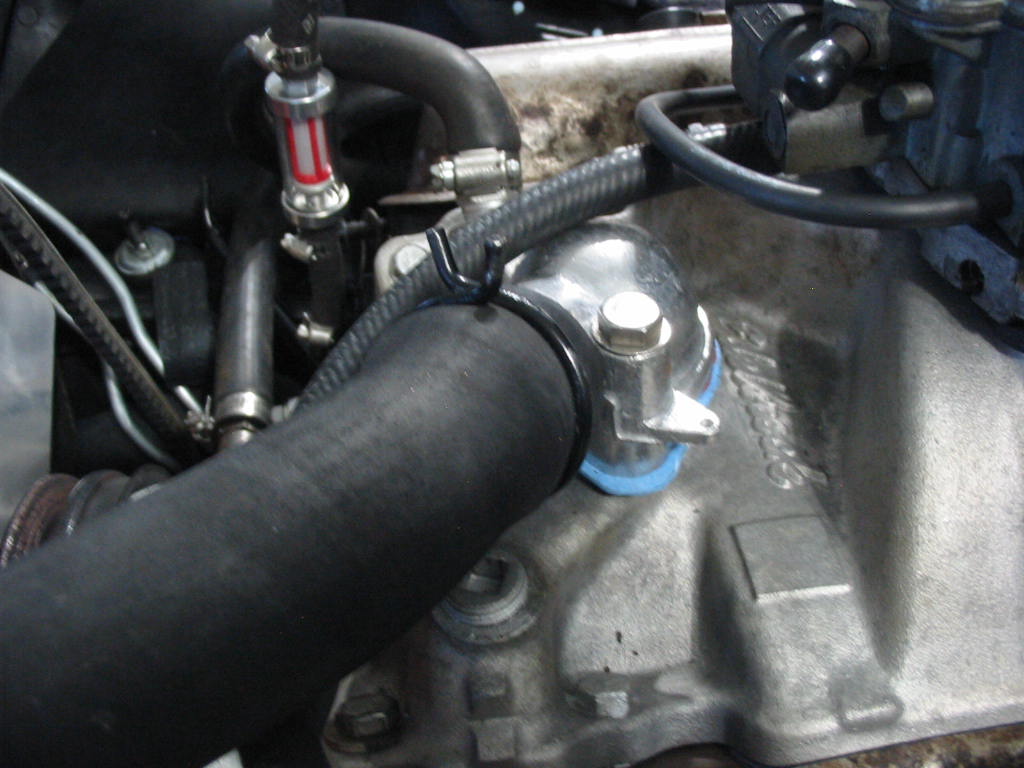

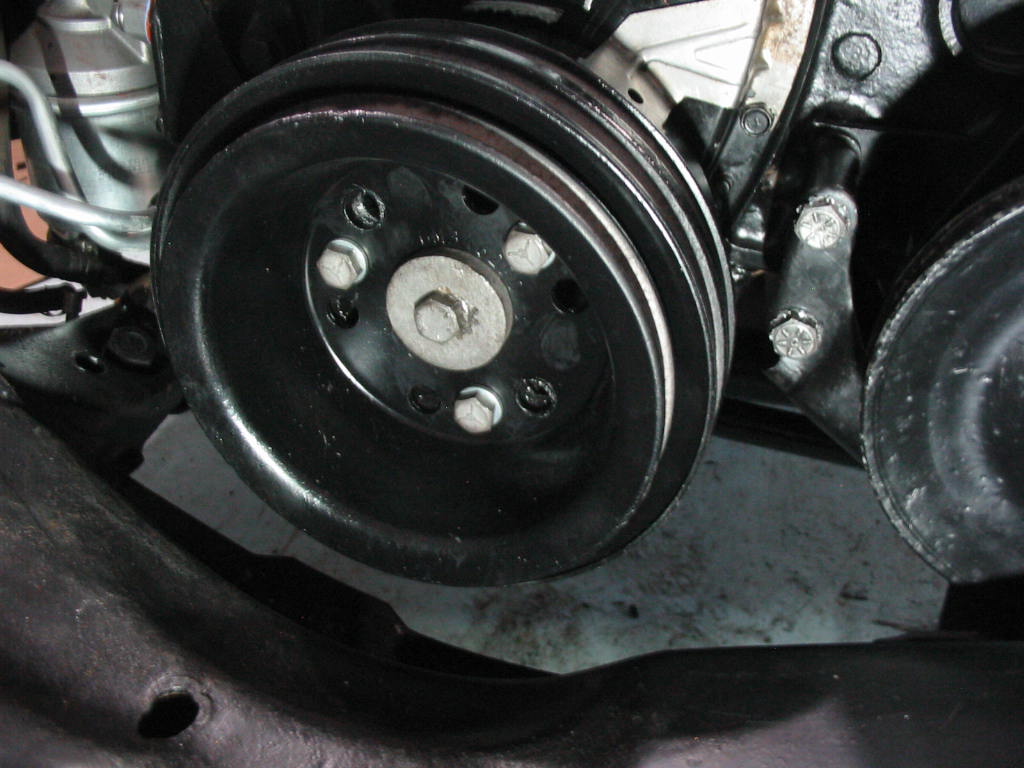

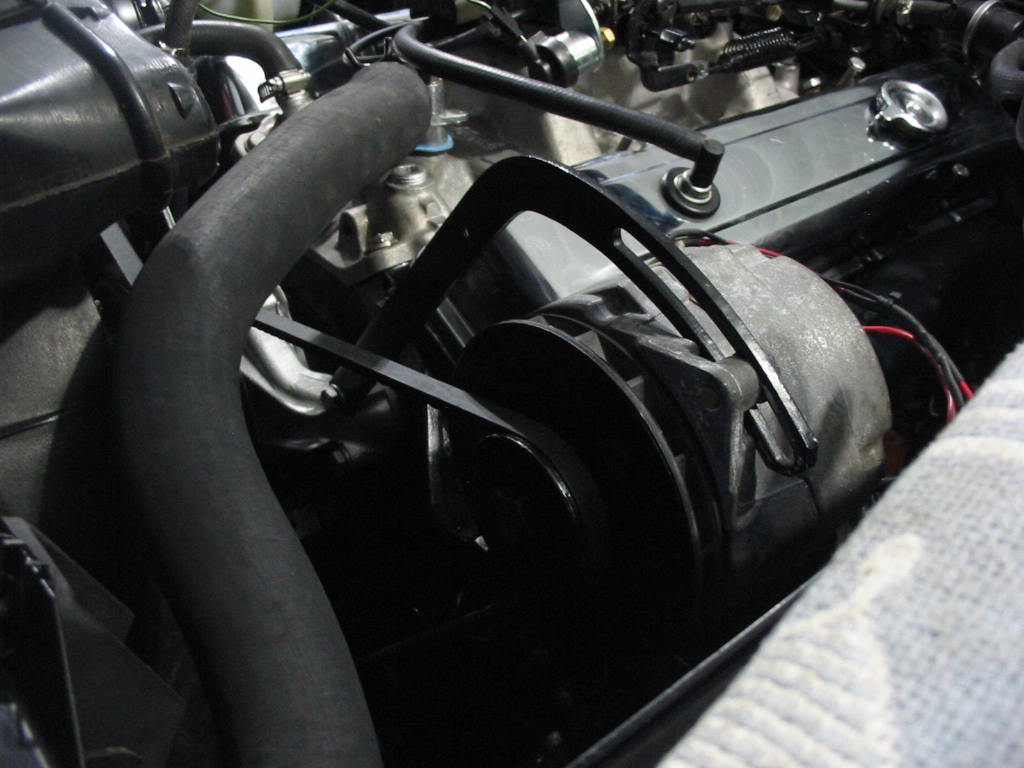

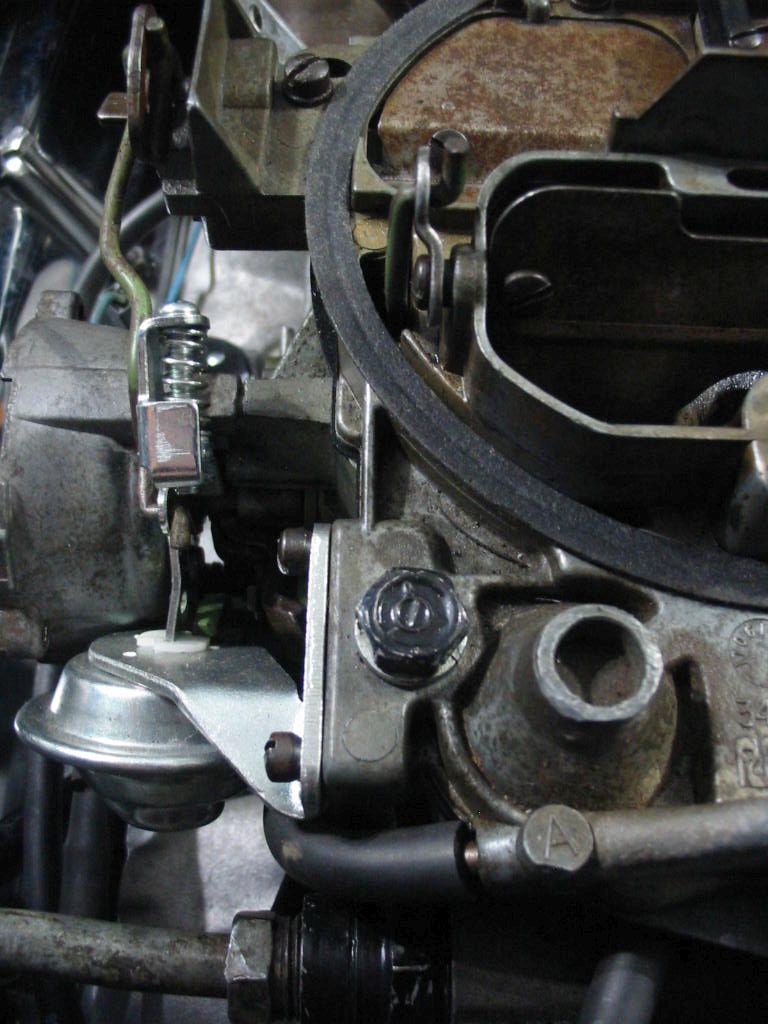

The Caprice 56 amp alternator in place and working fine.

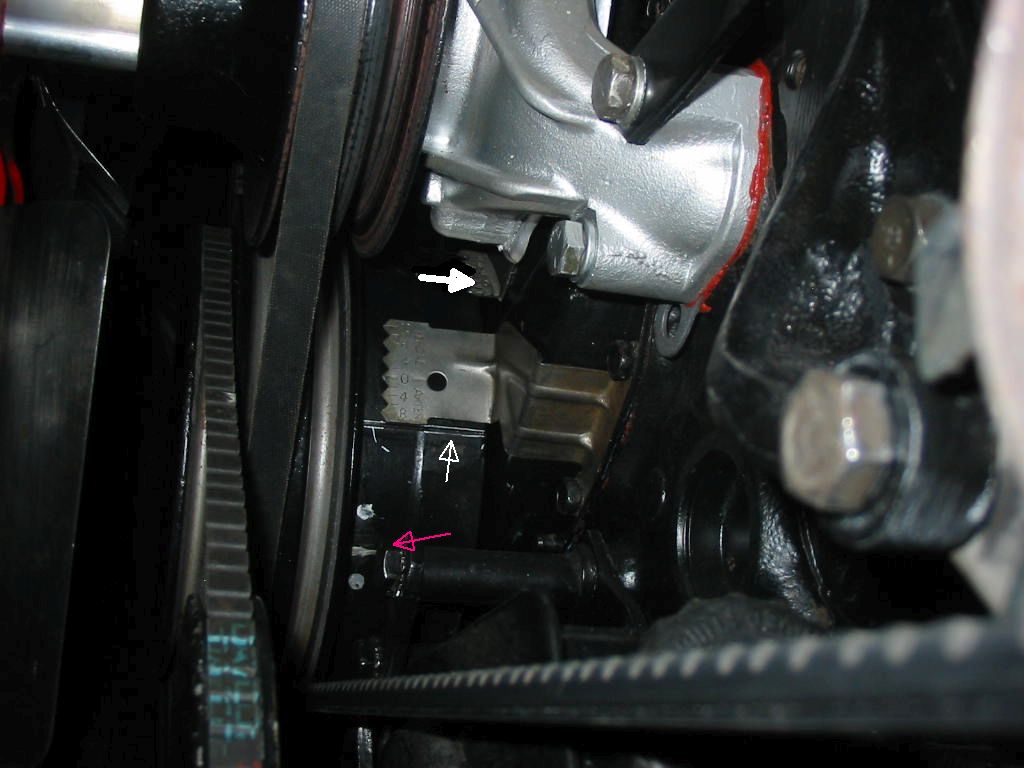

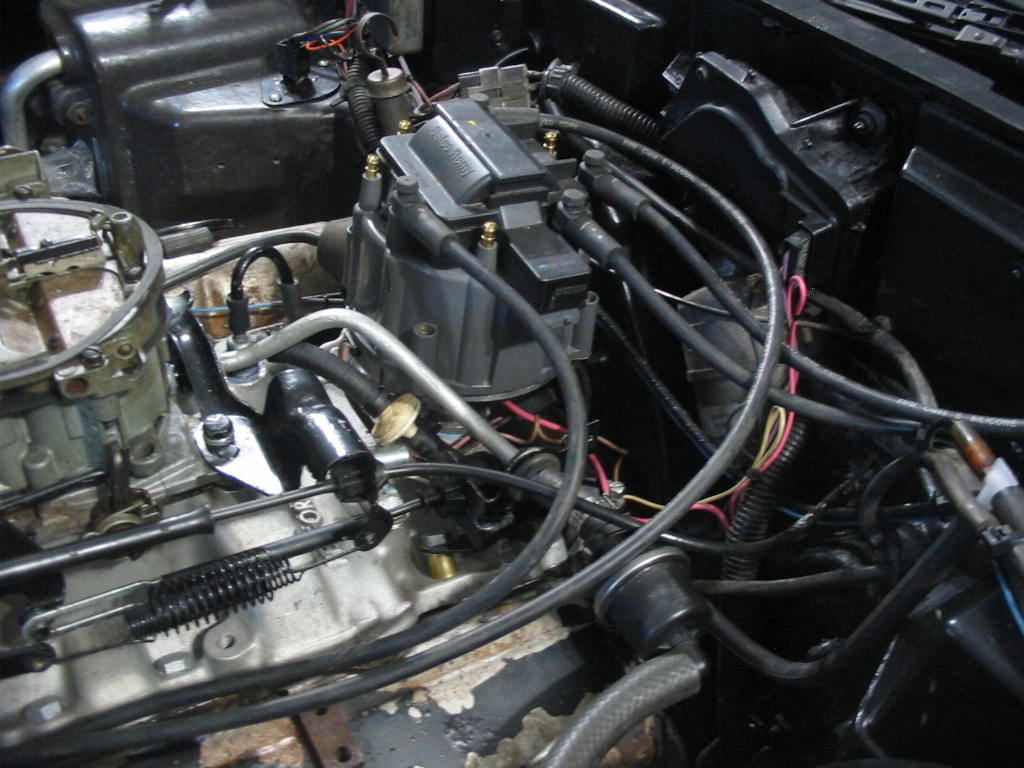

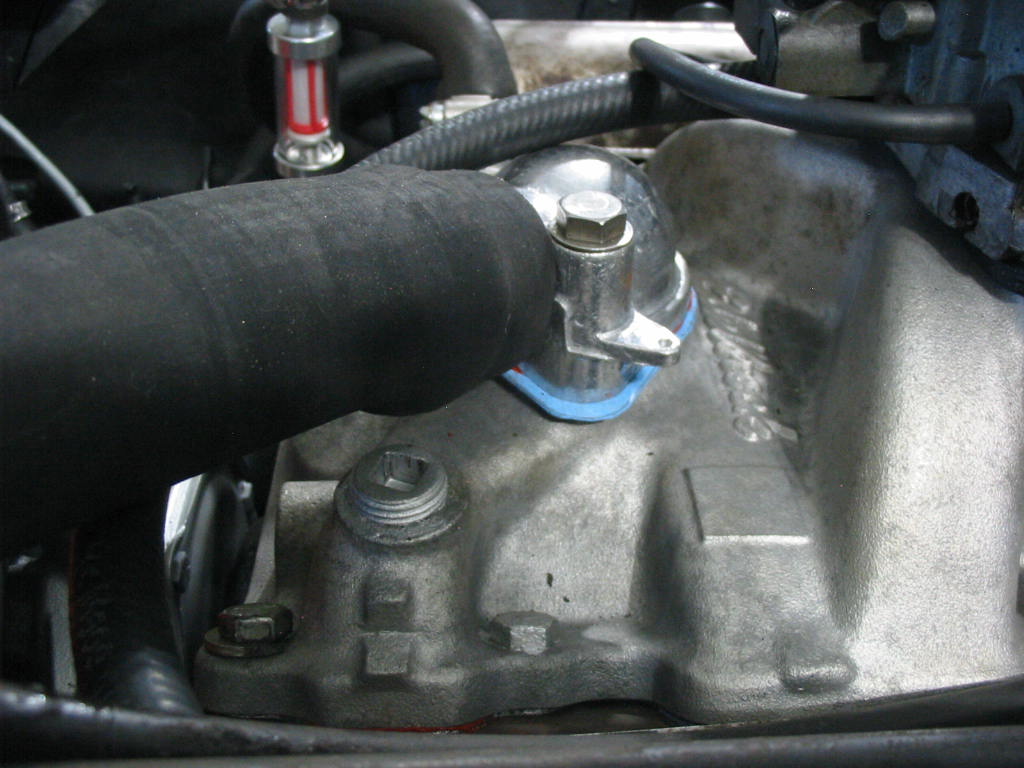

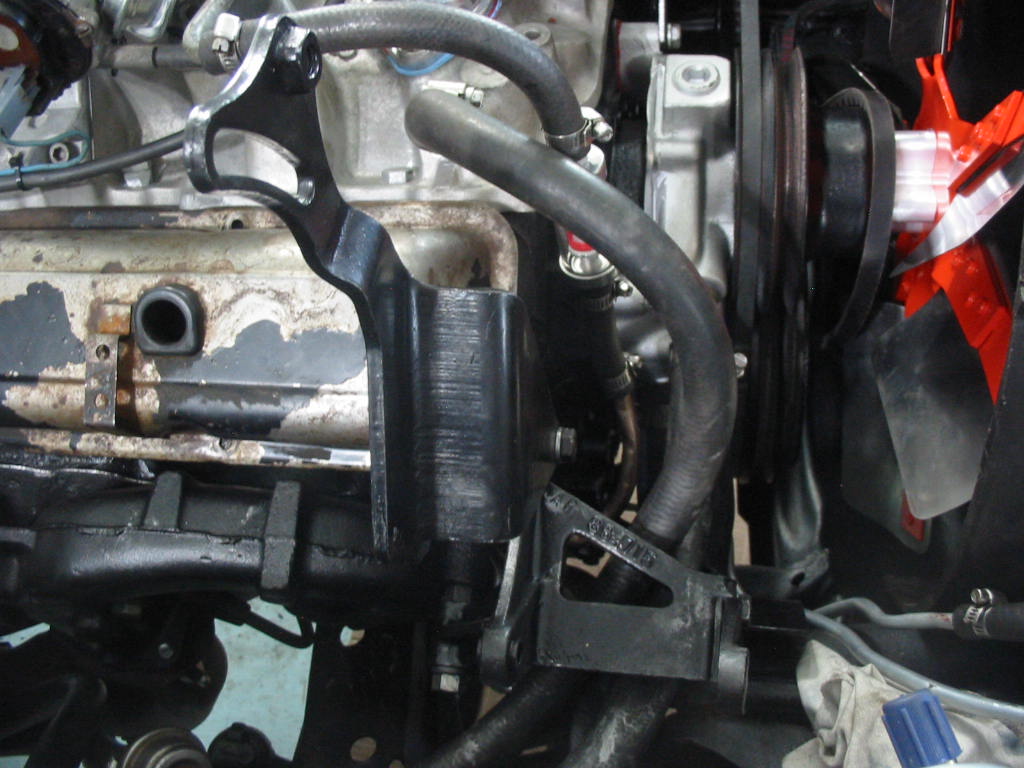

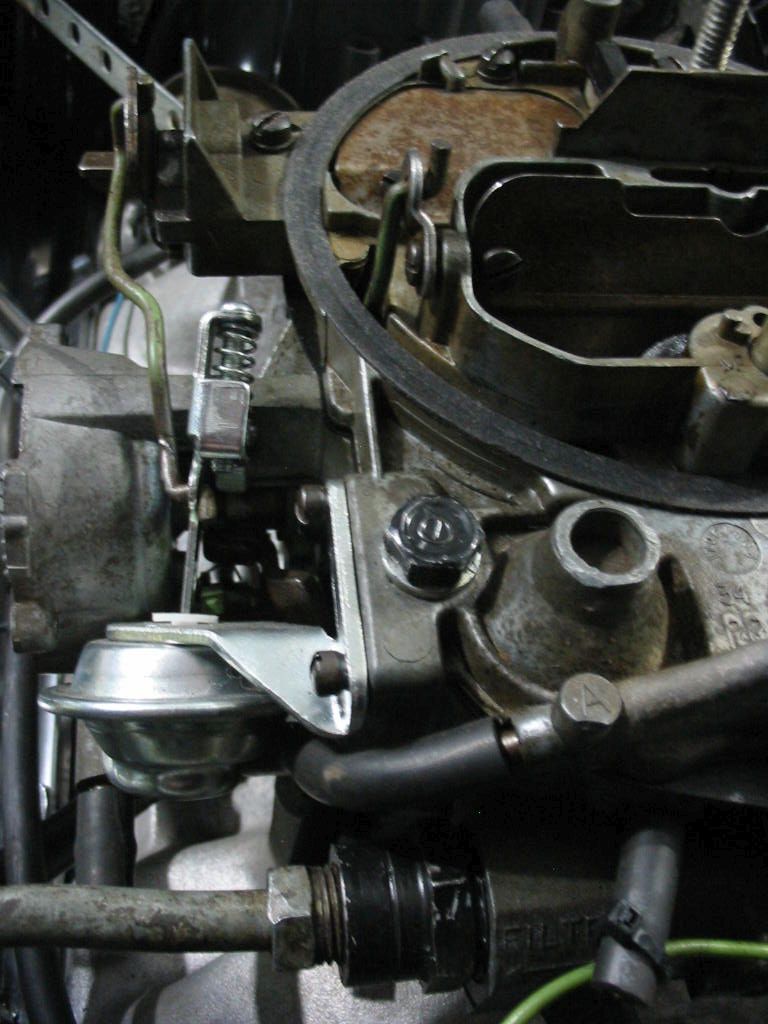

My second problem was that the choke flap wouldn’t close when I pressed the accelerator with the engine cold. I finally traced it down to the aftermarket vacuum dash pot. The linkage was getting in the way of the choke linkage. Just enough to hold the choke open until you fiddled with the choke arm.

The solution was to put a wee bend in the arm to keep it free. Once this was done the electric choke mechanism moved smoothly and the engine started and warmed up nicely.

Next: if there are no more bugs it’s time to start tearing down the original 350 🙂